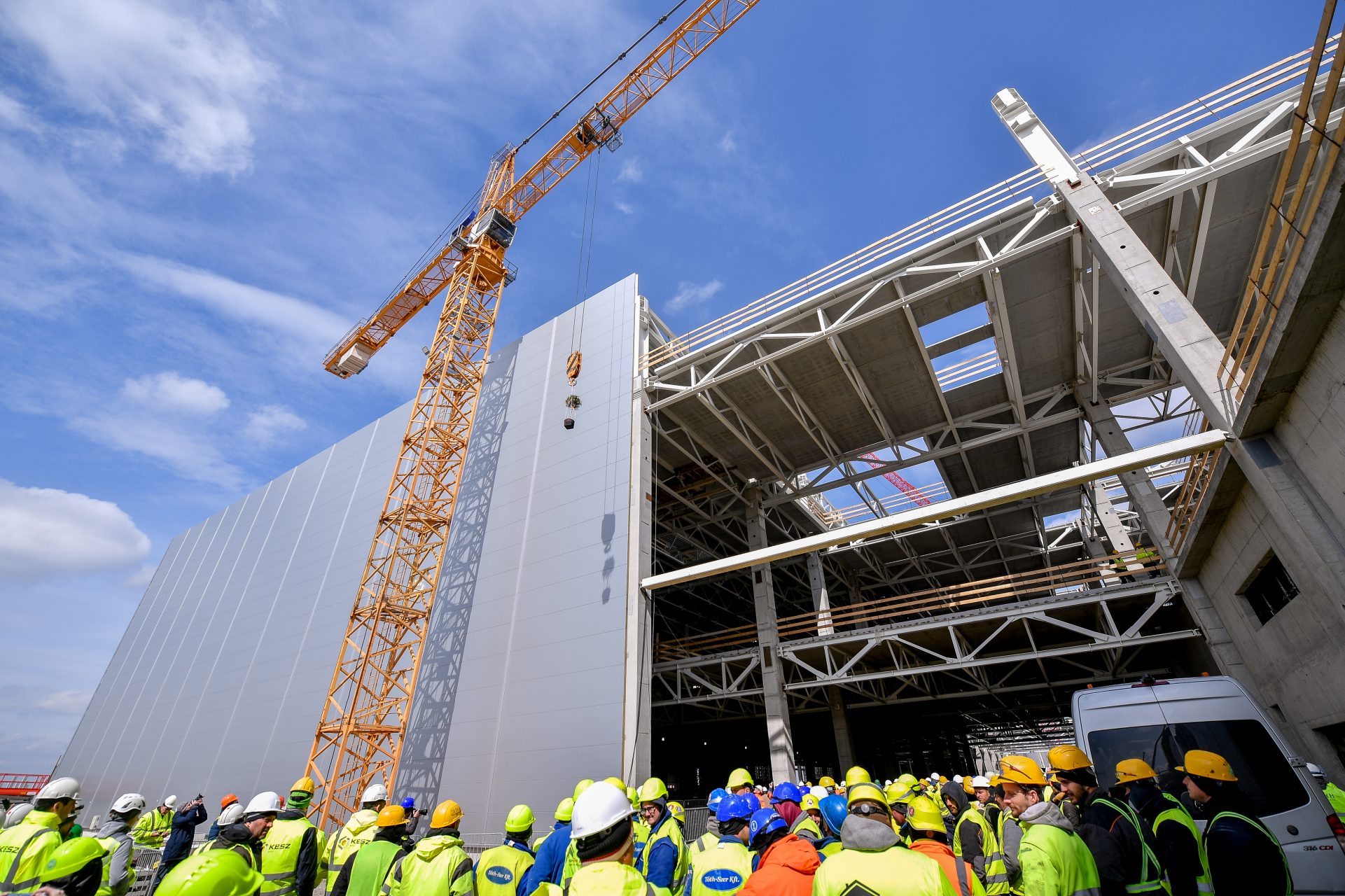

The construction of BMW Group Plant Debrecen has made a remarkable progress in the past period as now buildings are gradually taking shape and getting recognizable day-by-day. As a result of this momentum, the tallest building of the future plant, the Paint Shop reached its highest point, which served a perfect event to honour the construction workers for all their efforts so far – together with the main construction partner KÉSZ Group.

The Paint Shop is not only the tallest, but also the most challenging building of BMW Group Plant Debrecen, with its 90,000 sqm floor area and 26 meters height. Due to the next level sustainability requirements, it is the first time that all the latest,technologies available will be integrated into the three-story facility. From one side, this makes its construction a truly complex task, but from the other side, the technology and the knowledge gained from this benchmark building could be utilized at further BMW Group plants worldwide.

“This building, the Paint Shop means a lot for us. Every time you’ll a see a NEUE KLASSE model on the road, think about this building and the contribution you made to that with your work here” – addressed the construction workers Hans-Peter Kemser, President&CEO of BMW Manufacturing Hungary Kft.

The Debrecen plant will be the very first unit within the whole BMW Group to be designed entirely along the iFACTORY concept from the initial planning phase, in the spirit of three main pillars of the future of automotive production: LEAN, which stands for efficiency, precision and extreme flexibility, GREEN, for sustainability, resource-efficiency and circularity, and DIGITAL, for the active use of digitalization in data science, artificial intelligence (AI) and virtualization.

BMW Group Plant Debrecen will meet high sustainability standards. This includes, among others, planting 4500 trees, using rainwater and green energy for production. Moreover, they’re already working on a long-term biodiversity strategy for Plant Debrecen. At the Richtfest, as part of resource-saving approach, they used a living tree that will be ball planted at the site soon.

„With this plant, BMW Group strengthens its commitment to this sustainable approach, especially with the NEUE KLASSE that will debut here in Debrecen and lead us to the environmentally-friendly future – added László Papp, Mayor of Debrecen.

To strengthen the lean and the digital pillars, more than two years in advance to the official launch of series production, vehicle manufacturing is already underway in the future plant Debrecen – digitally, at least, as Debrecen is the BMW Group’s first facility to be planned and validated completely virtually. The success of the virtual start of production is a testament to the high standards that can be achieved through the digitalization of the planning process.

The BMW Group is building a full vehicle plant in Debrecen with a press shop, body shop, paint shop, and assembly, as well as a high-voltage battery assembly unit, which will allow the in-house assembly of the battery cells into the battery housing. Located on an area of more than 400 hectares in the north-western part of Debrecen, the plant will start production in 2025 with more than 1,500 employees,

and the all-electric NEUE KLASSE will debut here at the same time.