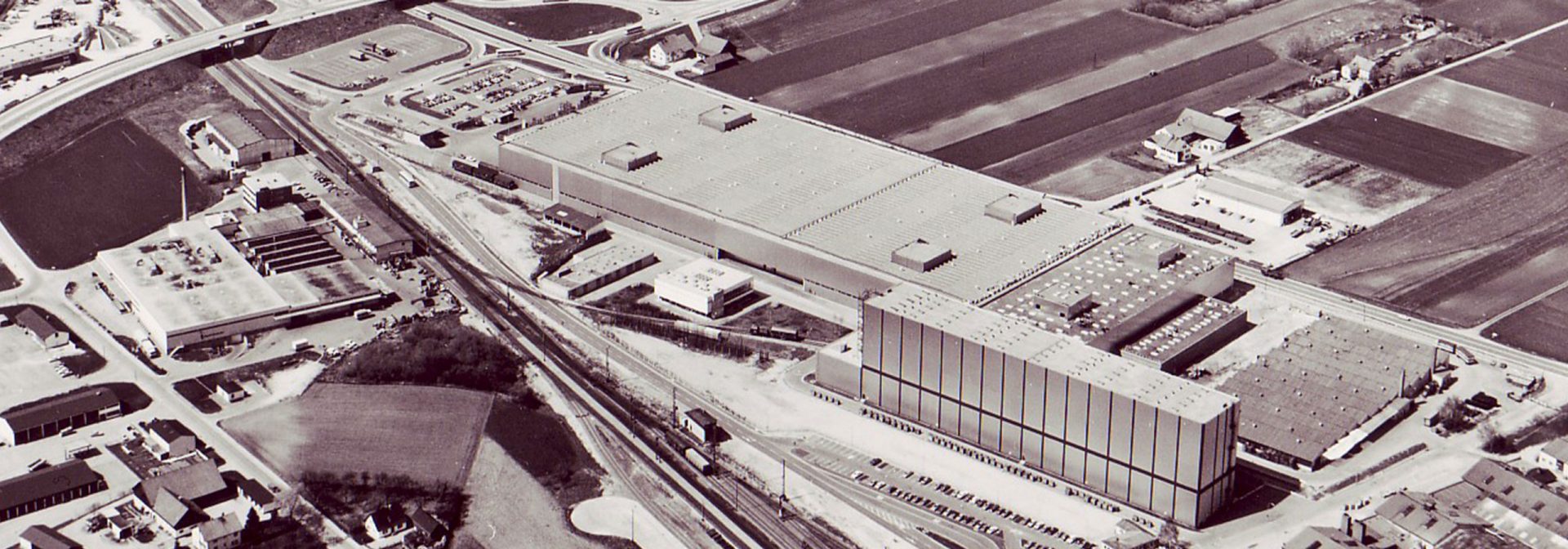

Following the economic crisis of the late 2000s, the recovery begins as early as 2010. The new, highly successful next generation of the BMW 5 Series is launched, to be followed by the new 6 Series one year later. Production output increases, reaching new record highs over the next few years. In 2014, for instance, Dingolfing builds almost 370,000 cars – also thanks to another expansion of the plant’s model lineup. Following a break of over ten years, 2013 sees the return of the 3 Series to the site, in the form of the BMW 3 Series Gran Turismo. From 2014 on, Dingolfing also manufactures the BMW 4 Series Gran Coupe, taking the total up to 5 model series and 15 different variants.

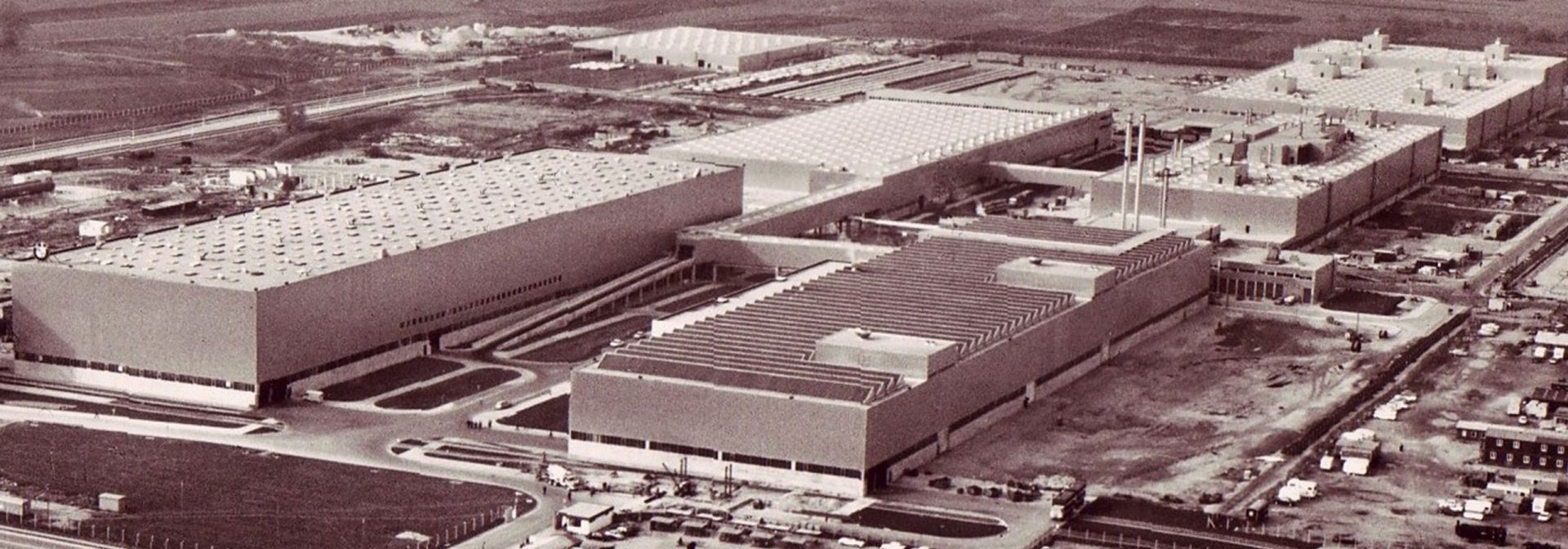

In late 2012, a major, multi-year plant expansion begins. With the so-called ‘westward expansion’ the plant prepares for future model generations and new technologies. Among the new facilities are a new body shop and a new CFRP production. Both are commissioned in 2015, with the launch of the new BMW 7 Series. Surrounding assembly, a new delivery center, a new automated small-parts storage and optimized traffic and material flows ensure that the site can manage the continuously increasing complexity.

With the new BMW 7 Series and its mix of materials – aluminum, steel and CFRP – the BMW Group and Plant Dingolfing set new standards in intelligent lightweight construction. On top of that, the site makes its mark as a center of excellence for the production of electric drive components. Due to the extensive aluminum expertise of Plant 2.1 and its experience in prototyping with alternative drives, the site has been providing Plant Leipzig with high-voltage batteries, electric transmissions and aluminum chasses for the BMW i electric models since 2013. From 2014 onward, construction is under way at Plant 2.2 for a new production facility for electric drives and high-voltage batteries to be fitted in future BMW Group plug-in hybrids.