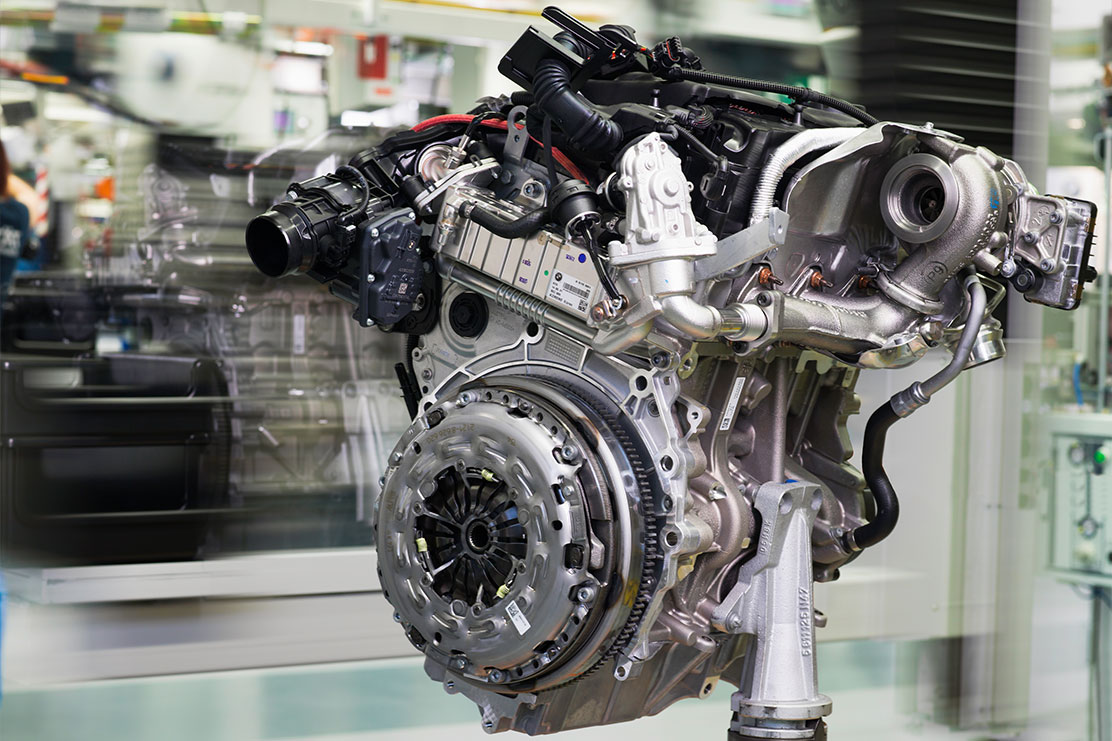

An engine consists of a variety of mechanical and electronic components, however, his heart are the crankcase and cylinder head. For the production of these components, the BMW Group sets depending on the requirement, a variety of materials. Correspondingly diverse and innovative are the applied casting methods. The cast components as well as the camshafts are processed in engine with high-precision computer-controlled machine tools, the employees take primarily controlling and setting tasks.

So all the parts of the engine, for example, examined in samples in Feinmess laboratory. The technicians measure the tolerance ranges no longer in tenths or hundredths but thousandths of a millimeter in (μ: 0,001mm). By comparison, a human hair has a diameter of about 0.1 millimeters.

This precision continues in the whole process of engine construction, whether conventional gasoline and diesel engines and special engines for BMW M models are manufactured. As before, the craftsmanship of the employees is in demand in engine: pistons and bearings are mounted, placed preassembled cylinder heads, aggregates, belt drives and cable mounted. If the engine is completed and running, the technique comes back into play. On so-called cold test stands, the motors undergo a final computerized test function.