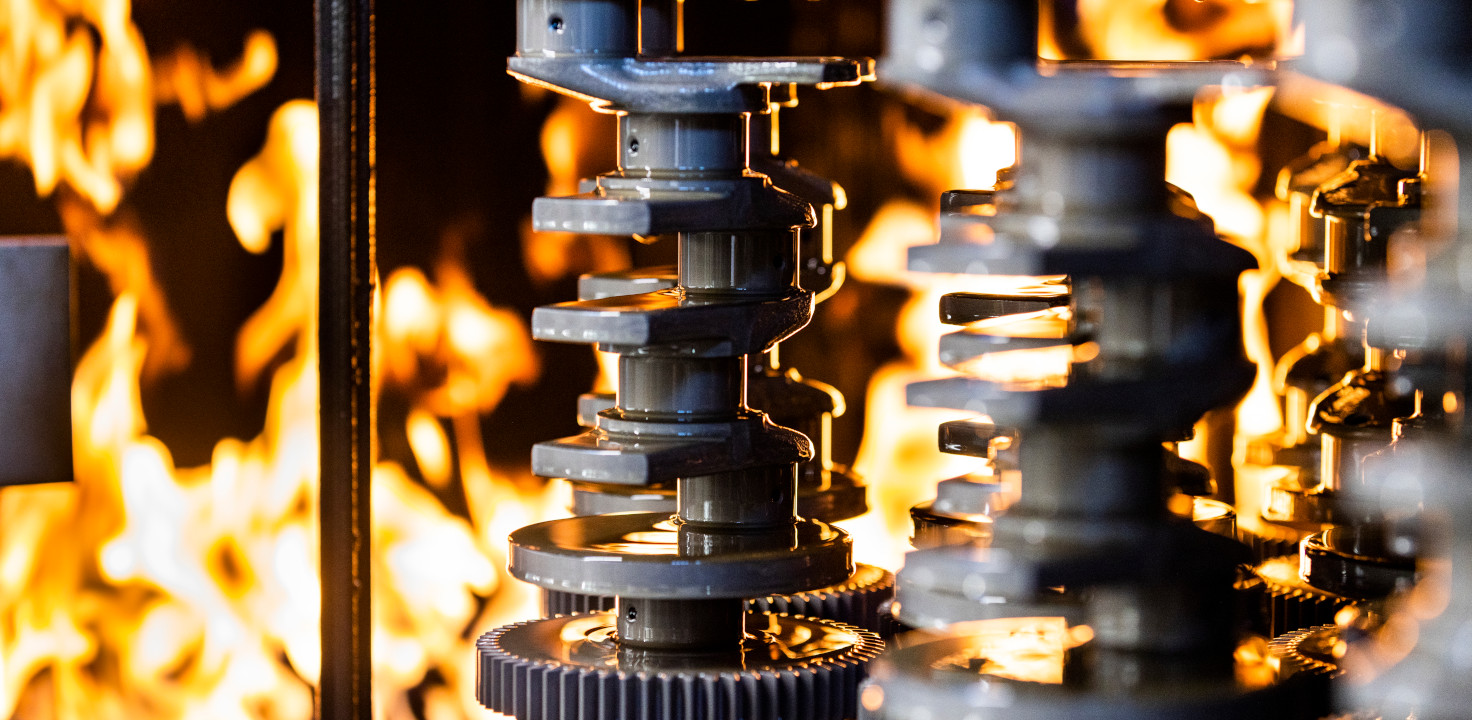

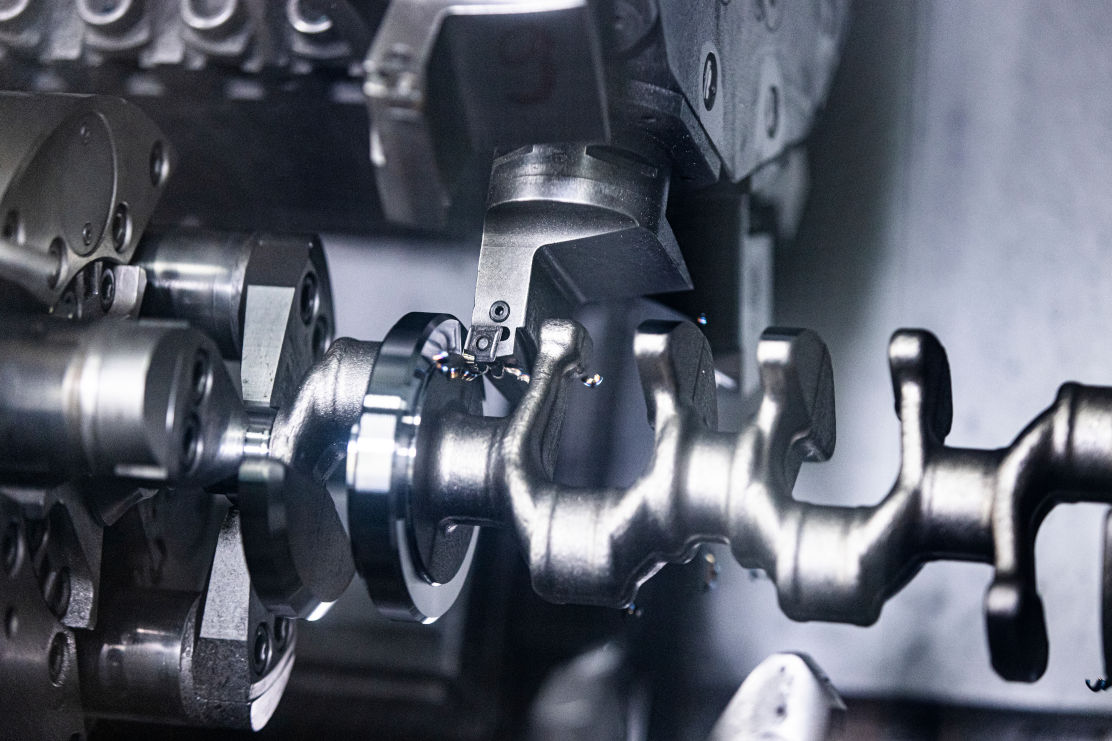

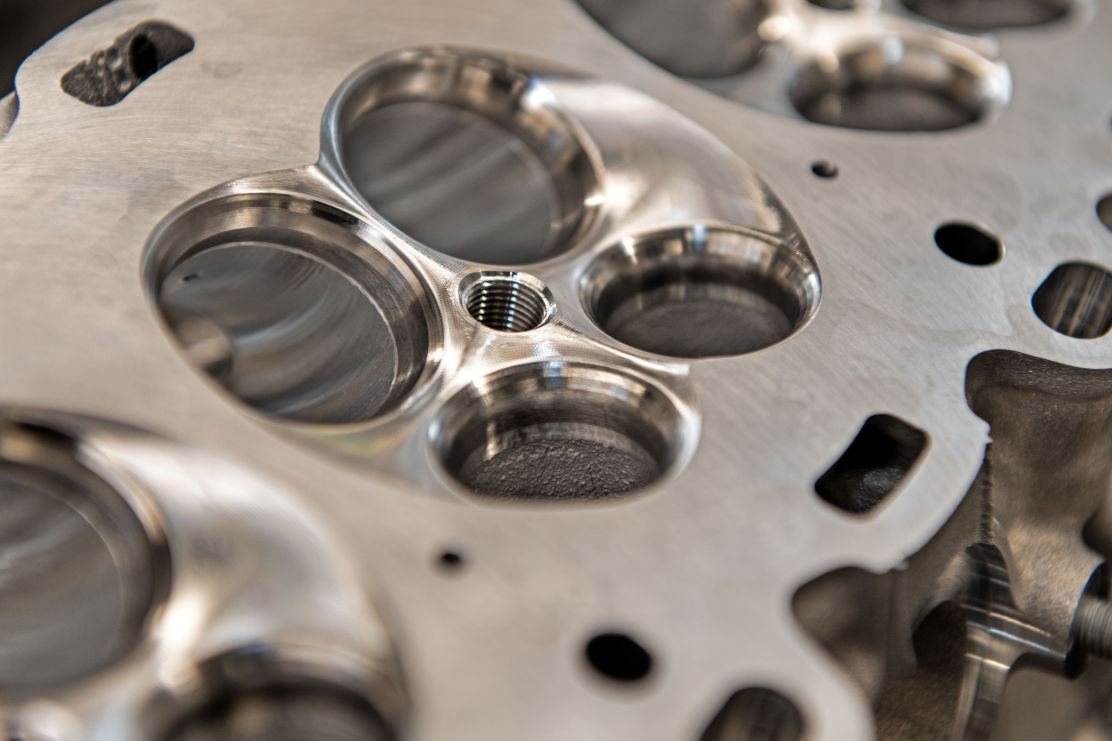

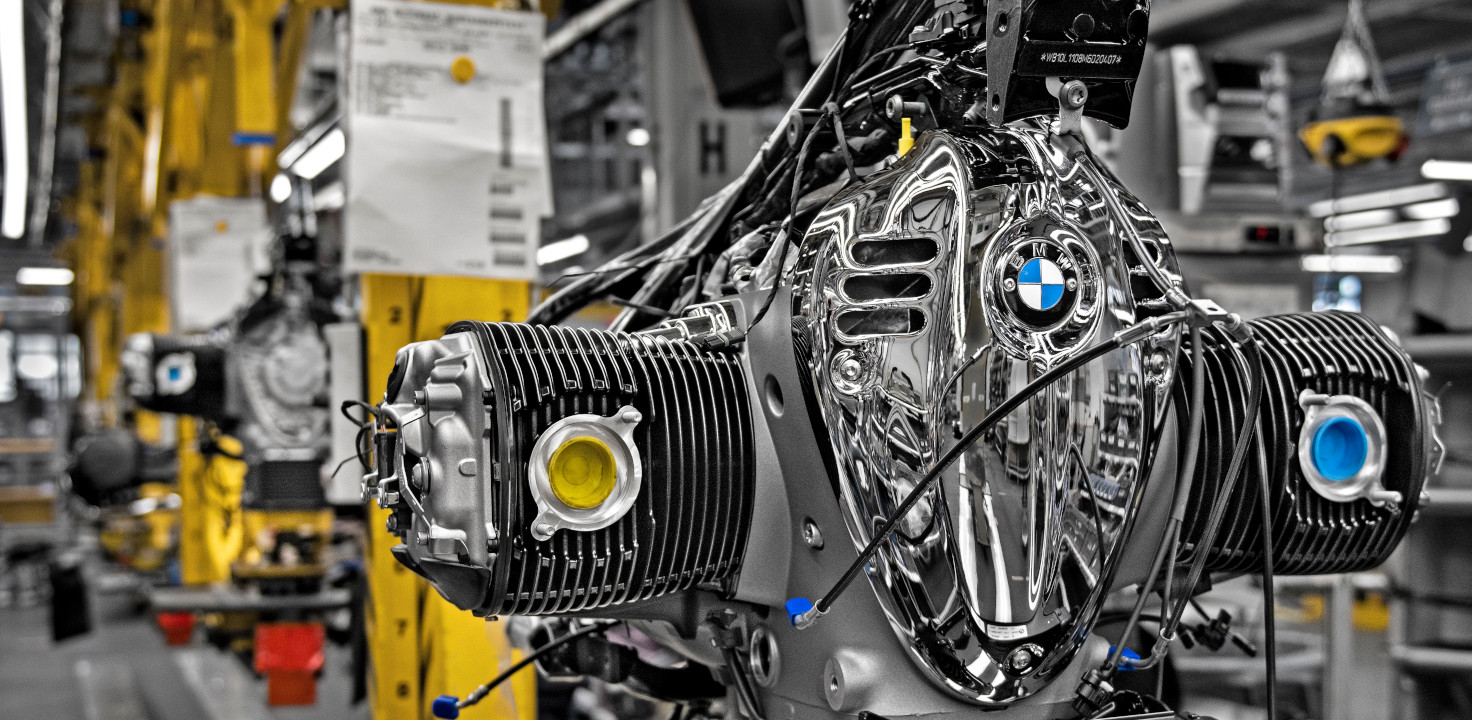

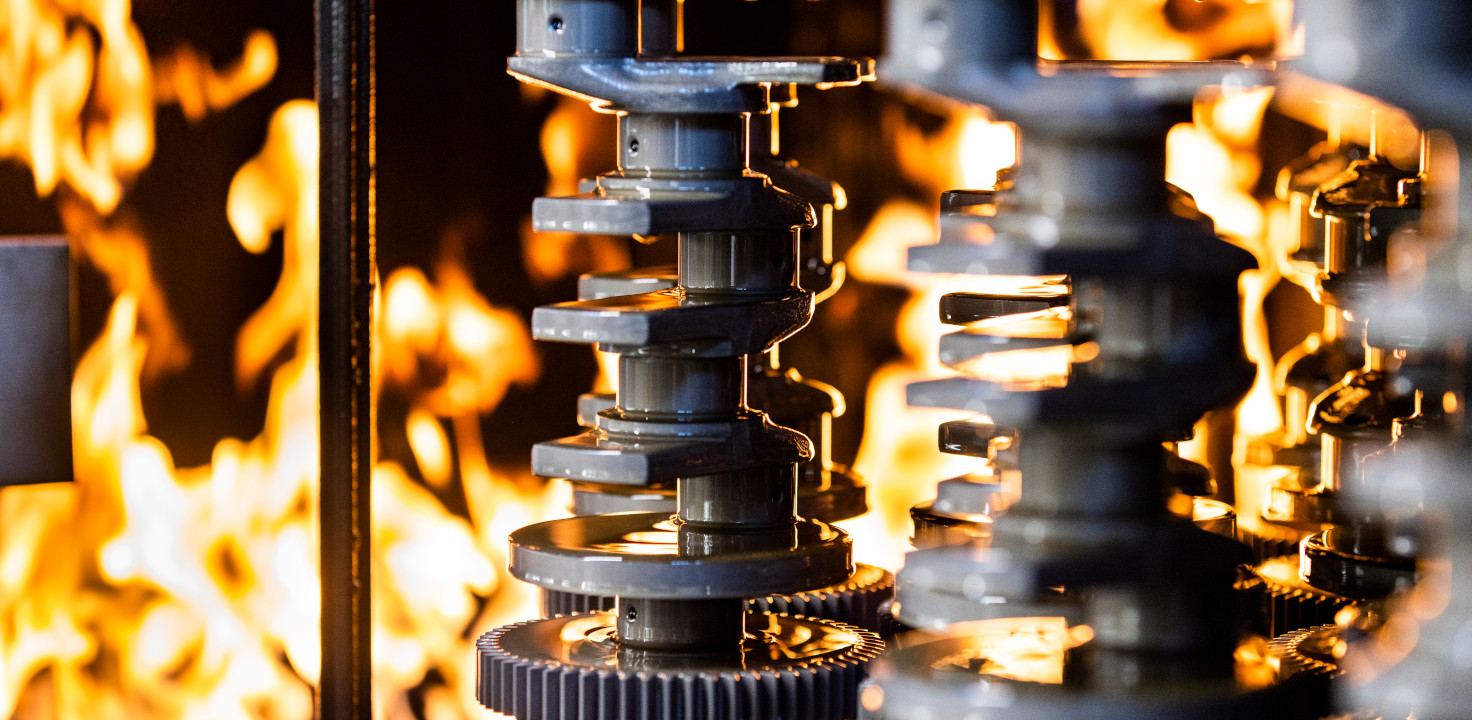

The machining shop is where the foundation of every motorcycle is laid. Key engine elements, such as engine cases, cylinder heads, crankshafts and connecting rods are produced here.

The machining shop produces about 4,000 parts a day in an 18- to 21-hour shift system. The machining shop’s unique building with its rounded roofs dates from 1914, but today houses state-of-the-art machinery. More than 140 CNC-controlled machining devices handle grinding, milling and finally polishing at the highest precision level and with maximum flexibility. The components are designed for tight tolerances down to one micrometer. This is remarkable considering that an average human hair measures about 60 micrometers in diameter. Components are continuously tested using high-quality testing and measuring technology.

The machining shop supplies the engine assembly at the Berlin plant as well as the locations in our international production network, namely the plants in Brazil and Thailand.