BMW Group Plant Steyr is the largest engine plant and one of the main development sites for BMW Group drive trains. The engines produced here are fitted in BMW and MINI cars at our vehicle plants around the world. The Steyr location is divided into different areas:

DRIVE TRAIN EXPERTISE FOR THE WHOLE WORLD.

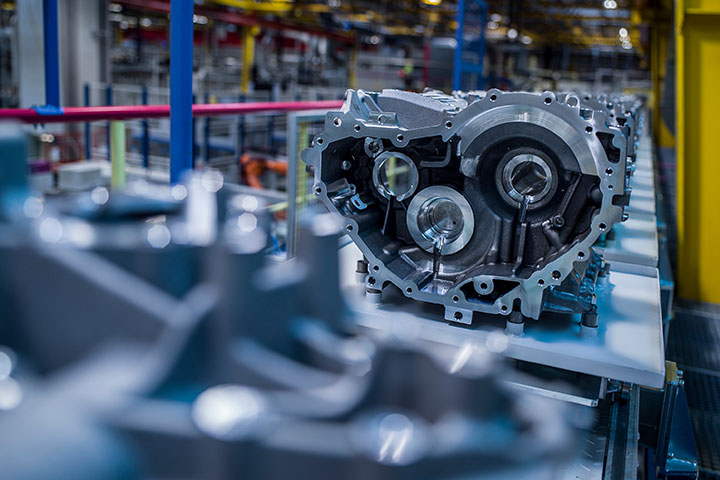

Engine assembly.

- This is where BMW and MINI engines are built from hundreds of individual parts.

- Three, four and six-cylinder petrol and diesel engines are all produced here.

- An engine rolls off the assembly line on average every 12 seconds

- Up to 5,500 engines per workday are produced at peak times.

- Two of the assembly lines will also build the next generation of electric drive trains from 2025 – reaching more than 600,000 per year in the final stage of expansion.

Mechanical production.

- State-of-the-art machinery is used to ensure high-precision mechanical machining of parts.

- Core components for diesel, petrol and electric engines, such as connecting rods, cylinder heads and housings, crankshafts and e-drive housings, are also produced.

- These core components are fitted both in engine assembly in Steyr and at other BMW Group production locations.

Steyr development site.

- Steyr is home to the Group-wide competence centre for efficient, dynamic diesel engines.

- It also develops the e-drives for high-volume smaller BMW Group vehicle series.

- Heat management systems (heating and cooling) for fully-electric vehicles are also developed at the site.

- Going forward, an all-new high-performance e-drive that will take BMW M vehicles to new heights of electric performance will also take shape here.

Page Overview: BMW Group Plant Steyr