Work begins on BMW Plant Leipzig extension.

The main focus of activities at the plant is to increase annual production capacity by approx. 100,000 units, from the current 250,000 to about 350,000 p.a. in 2020. Production of BMW i models will rise much earlier, in autumn of this year, from 130 to 200 units a day to meet the welcome growth in demand. “We have every faith in the skills and productivity of employees at our Leipzig plant,” said Oliver Zipse, BMW AG Board Member for Production. “So it’s only logical that, with the measures we are introducing now, we should make the plant even more flexible and, above all, more efficient to keep it competitive in the future.”

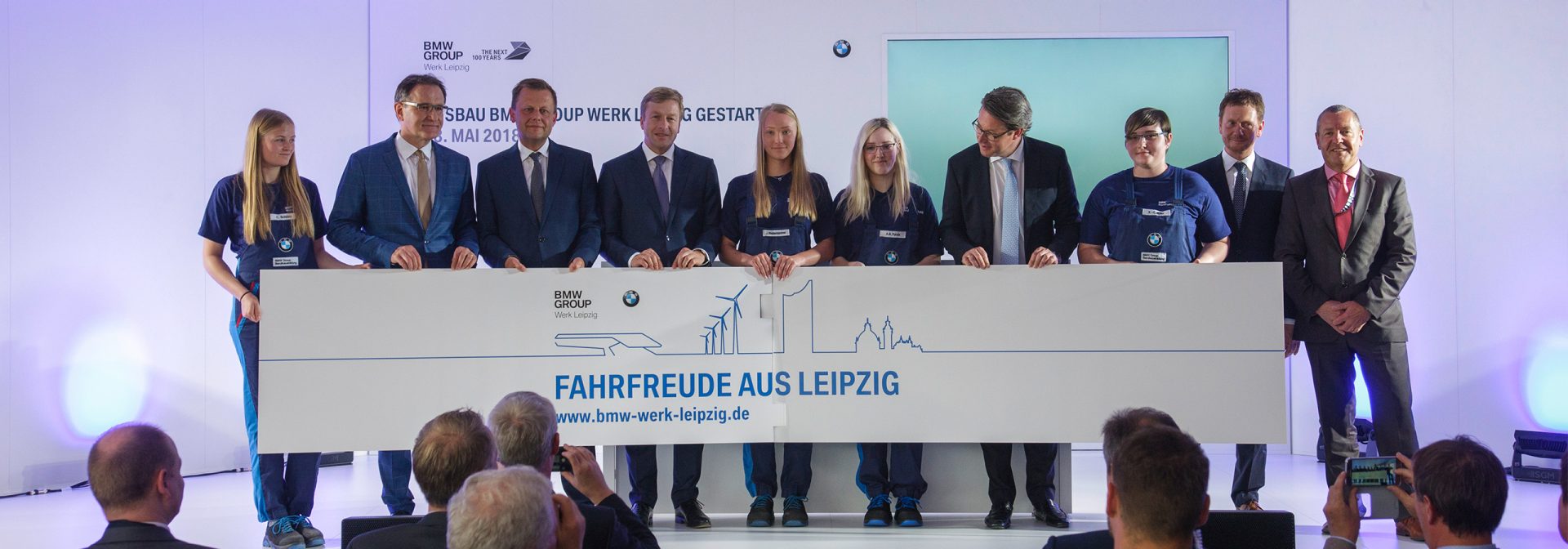

This important step for the company as well as the Leipzig/Halle region and the free state of Saxony was today honoured in the presence of the Minister for Transport and Digital Infrastructure, Andreas Scheuer; the Minister President of the Free State of Saxony, Michael Kretschmer; the First Mayor of the City of Leipzig, Torsten Bonew; the Board Member for Production, Oliver Zipse; Plant Director, Hans-Peter Kemser, and Works Council Chairman, Jens Köhler.

Andreas Scheuer, German Minister for Transport and Digital Infrastructure: “Germany is the land of mobility. The automotive industry is our leading sector – and that’s not about to change. It has created jobs for hundreds of thousands of people and will continue to do so in the future. We now have the chance to bring new German drive technologies onto the market, and must make electric mobility real for people and convince them with performance.”

Minister President Michael Kretschmer: “This plant extension is a clear sign which will strengthen Saxony even further as an industry base and secure good jobs for the Leipzig region. I am delighted that BMW remains faithful to Leipzig and continues to make major investments here.”

“What’s most important to me, as Plant Director, is our company’s clear show of trust in our employees and our region,” said Hans-Peter Kemser. BMW Group Plant Leipzig first launched series production in March 2005, with 2,000 employees. Another 3,300 jobs have since been created, taking the total headcount to over 5,300 today. Since series production was first launched, in March 2005, more than 2.3 million vehicles have rolled off the production lines

in Leipzig, and investments have totalled approx. €3 billion.

Works Council Chairman Jens Köhler emphasised: “Today is an extremely important day for our employees. These investments will secure our jobs here in Leipzig and ensure our plant is future-proof.”

Flexibility is gaining major importance in automotive production

The BMW Group is currently preparing all of its plants to integrate fully electric vehicles into their existing structures so that they can produce combustion-powered, hybrid and fully electric vehicles simultaneously.

BMW Group Plant Leipzig is no exception. Here, pioneering work has already reinvented and revolutionised the manufacture of electric and plug-in hybrid vehicles, leading to the launch of BMW i3 production in 2013, followed by the BMW i8 in 2014 and the BMW i8 Roadster in March 2018. Meanwhile, classic production at the site has been consistently extended throughout. Leipzig’s years of expertise in the field of electric vehicle production is now being rolled out across the BMW Group’s global production system.

“We are taking the invaluable knowledge from Plant Leipzig to facilities across our production network. Current production of the BMW i3 and BMW i8, in independent structures, will continue unaffected. Over the longer term, Leipzig will gradually develop further, capitalising on the opportunities of digitalisation and becoming more flexible to enable vehicles with any type of powertrain to be produced together on a single assembly line,” Plant Director Hans-Peter Kemser explained.

Conversions under way throughout the plant

The rise in annual output of 100,000 units up to 2020 will be enabled by comprehensive extensions and conversions in all the core technologies. The latest system technologies will be introduced, processes and structures reviewed and refined, and existing facilities extended.

Paint shop – larger, more efficient, even more sparing with resources

The main focus of the developments at Plant Leipzig is the paint shop. This will be extended by 300 m to the north and south, with new buildings covering an area of 11,950 m2. The key features will be a second fully automated top-coat paint line in the south extension, and a new pre-treatment system and cathodic dip in the north. Together, they will increase paint shop capacity by more than 40 percent. The introduction of cutting-edge IPP (integrated paint process; filler-free) technology will reduce energy consumption per unit by 15 percent, water consumption by about 30 percent, and wastewater production by roughly 45 percent. In the medium-term these resource-friendly technologies will also be integrated into the existing paint shop line.

Body shop – new industry robots and more

Structures and process systems in the bodyshop will also see modifications, with almost 500 additional cutting-edge industry robots to be fitted over the next few years. Further adjustments will be made to conveyor systems, laying the foundation for production of future models. In addition, Plant Leipzig will gain importance as an in-house supplier of doors and lids within the BMW Group production network.

Assembly – intelligent machine assistance through digitalisation

Assembly is also being upgraded, with a completely new panorama roof fitting system already added in March of this year. The 40-tonne piece of high-tech equipment is faster, more flexible and can fit considerable more variants than its predecessor.

In addition, preparations are under way for the targeted use of human-robot collaboration systems. These require no protective barriers and therefore allow robots to support associates even more closely as they work. One such system is already in operation, bonding windscreens into the BMW i3.

Assembly is also to be extended, with some 3,500 m2 being added to its existing footprint to create space for the additional workstations required for future models.

Logistics – perfect flow of goods; pilot projects for emissions-free transport

Perfect logistics are the backbone of automotive production. With several thousand components needed to make personal mobility on four wheels a reality, the €300 million investment in Leipzig will also focus on adjustments and optimisations to material flow systems.

Activities will centre on a value-stream focus – on short, efficient, well thought-out and therefore waste-free part flows and workflows throughout the plant.

As elsewhere, digital technologies are increasingly taking hold in everyday logistics. Some solutions are still being tested, such as logistics systems for autonomous container feeds, or the use of hydrogen-powered industrial trucks, which is currently being tested in a further pilot project with partners. The hydrogen vehicles will allow zero-emissions logistics on the plant premises and have their own refuelling facilities within the production halls.

Medien-Anfragen

Leiter Presse-/Öffentlichkeitsarbeit und Mitarbeiterkommunikation

BMW Group Werke Leipzig, Berlin, Eisenach